Winner

Open Design Award

Core77 Design Awards 2015

Open Gigabot : An Open Source, Gigabot 3D Printer Experiment

This story is about YOU

Open Gigabot is a HUGE, open-source, feature-rich, networked, touchscreen Gigabot concept 3D printer customized around your hardware and software demands.

As the world's first affordable, industrial large format 3D printer, Gigabot has paved the way for accessible human-scale 3D printers. After fulfilling a successful $250k Kickstarter last year, our re:3D team surveyed our customers, looked at market data, and gathered insights to discover interest in customizing Gigabot's ultra-accessible frame. Now, we're turning to the community to crowd-source and crowd-fund the integration of new features. Open Gigabot (OpenGB) is an experiment in improving the usability of our printers, while also expanding hackable elements on large scale 3D printers - which is why we're sharing it with you, the Core77 community.

Inside Open Gigabot

Whether you're working from a home office setting or launching a garage business, Open Gigabot is built to empower your 3D printing experience! And the best part about it is, we're co-developing these features with you while we build them into the final production version :

1. Open Software

2. Open Hardware

3. Wirelessly Networked

4. Touchscreen GUI, Mobile Interface

5. Watch-Dog Reliability

6. Cat-Proof, Baby-Proof

7. Optimized Footprint

8.Large Scale Build Area [ 24 x 24 x 20 in ]

Community-First Approach

Open Gigabot is a limited-run (15 unit) concept 3D printer, currently raising awareness and its R+D budget on Kickstarter. Our focus is to bring you, the community, into the design process so that we create the most personal, most maker-accessible, and most inherently useful human-scale 3D printer on (or off) the planet.

Our community is our company's biggest asset. We love, contribute to, and breathe Open Source. Not only is community important to us, it is the lifeblood of our innovation economy.

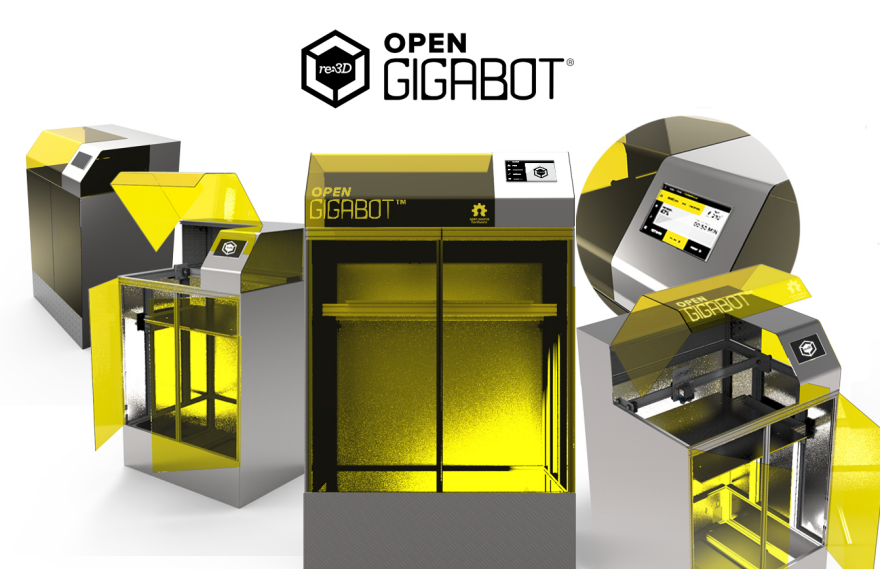

Open Gigabot Production Design Rendering

Open Gigabot Production Renderings

Open Gigabot Production Design Rendering

Open Gigabot Production Renderings

Open Gigabot Prototype Unit

Home Office Setting

Open Gigabot Prototype Unit

Home Office Setting

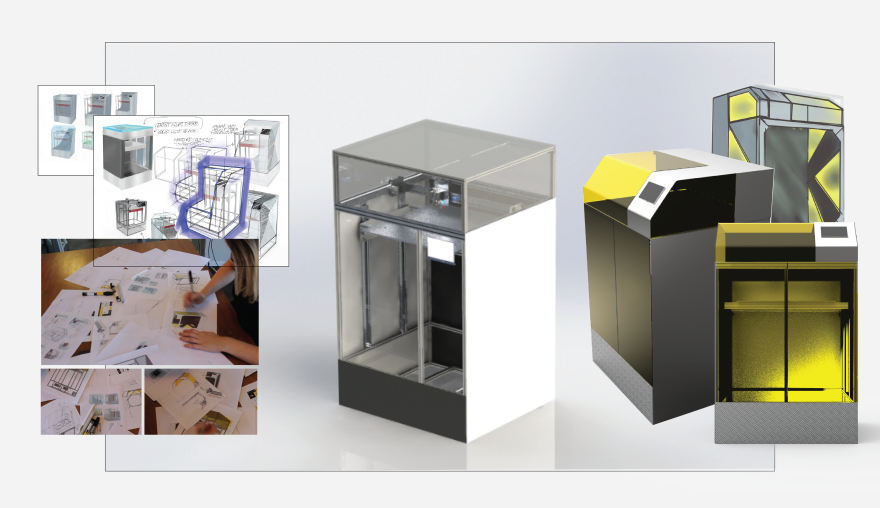

Open Gigabot Design Process

Open Gigabot Design Process

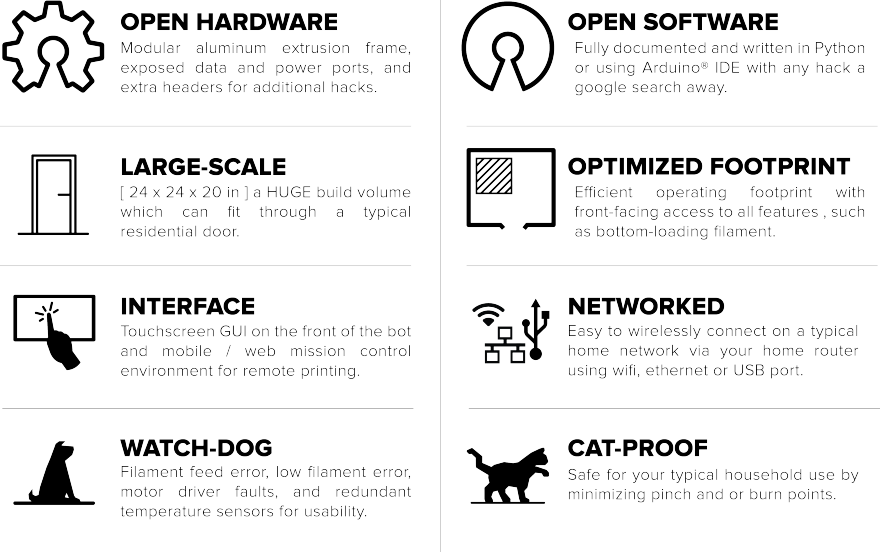

Open Gigabot Features

Open Gigabot Features

Open Gigabot is Cat-Proof

Open Gigabot is Cat-Proof

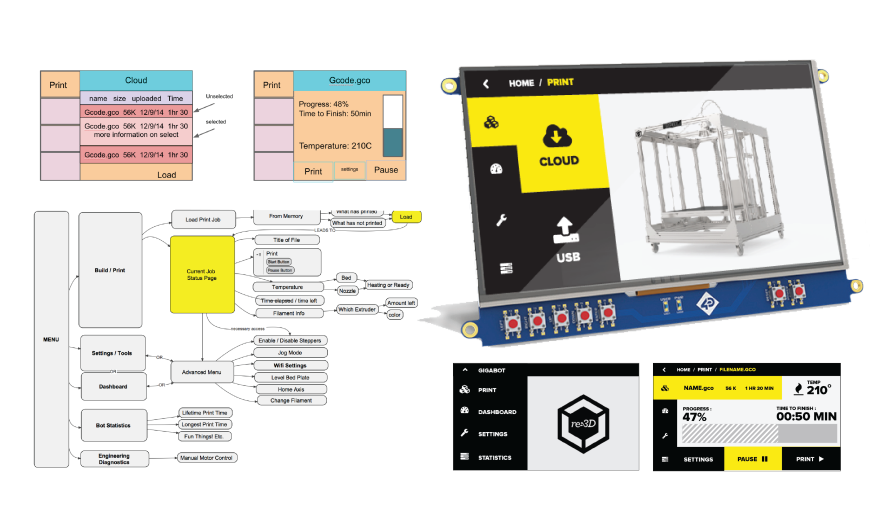

Open Gigabot Touchscreen GUI

Open Gigabot Touchscreen GUI

Open Gigabot Touchscreen GUI

Open Gigabot Touchscreen GUI

Launching Open Gigabot Kickstarter

SXSW Create Tent; First tier of OpenGB's gone in the first 12 hours

Launching Open Gigabot Kickstarter

SXSW Create Tent; First tier of OpenGB's gone in the first 12 hours

re:3D Open House

Community Feedback on Open Gigabot Product Development

re:3D Open House

Community Feedback on Open Gigabot Product Development

Open Gigabot Prototype Unit

Hood Design

Open Gigabot Prototype Unit

Hood Design

Open Gigabot Team

Katy and Mike sketching OpenGB's Information Architecture

Open Gigabot Team

Katy and Mike sketching OpenGB's Information Architecture

Inside Open Gigabot

People love to customize their Gigabot. OpenGB's concept was designed with Gigabot experiments and community input in mind. By building this product with the Kickstarter community, we are creating the proving ground for the integration of new features and ensuring that our production line is done right.

With this in mind, we are re:imagining your 3D printing experience from the ground up in these 8 ways :

1. Open Software : Community-credited, written by re:3D, and fully documented.

2. Open Hardware : Modular aluminum extrusion frame with exposed ports.

3. Networked : Wirelessly connect and control using wifi, ethernet or USB port.

4. Touchscreen GUI, Mobile Interface : Front-facing touchscreen GUI on the bot AND mobile/web interface for remote printing.

5. Watch-Dog Reliability : Filament feed error, low filament error, motor driver faults, and redundant temperature sensors for usability.

6. Cat-Proof, Baby-Proof : Safe for your typical household use by minimizing pinch and or burn points.

7. Optimized Footprint : Efficient operating footprint with front-facing access.

8.and of course, Large Scale : [ 24 x 24 x 20 in ] a HUGE build volume to fit through typical residential doors.

Open Source, End-to-End

OpenGB seamlessly packs hacks and features floating around the 3D printing community into an all-inclusive experience. Many of our components are sourced from open source pioneers and we're specifically targeting open platforms with a global perspective. The OpenGB prototype incorporates these platforms into the command, control, and general 3D printing workflow.

Every part of the Open Gigabot 3D printer is designed to: first, provide you the best user experience; And second, let YOU decide what that is.

Mechanically the aluminum extrusion allows you to attach anything to the frame without drilling holes. Electrically we provide extra headers with 3.3v, 5v and 12v at both the control board and the extruder to add your own features. And all of the software is written in either Python or using the Arduino® IDE which makes the answer to any software question a simple google search way.

To enable all these new features we also created a brand new controller. Completely open source, it includes a host of small but important features to make it expandable and customizable.

Community-First Approach

Open Gigabot is a limited-run (15 unit) concept 3D printer, currently raising awareness and its R+D budget on Kickstarter. Our focus is to bring you, the community, into the design process so that we create the most personal, most maker-accessible, and most inherently useful human-scale 3D printer on (or off) the planet.

Our community is our company's biggest asset. We love, contribute to, and breathe Open Source. Not only is community important to us, it is the lifeblood of our innovation economy.

Really opens the door for smaller scale manufacturing

It solves a problem in that a lot of 3D printers are just not functional because they're too small.

I liked the fact that it has an app that you can use to control the 3D printer from afar...The fact that all the components, hardware and software, are all open source, gives it a lot of power, and the fact that it uses a large bed really opens the door for smaller scale manufacturing.